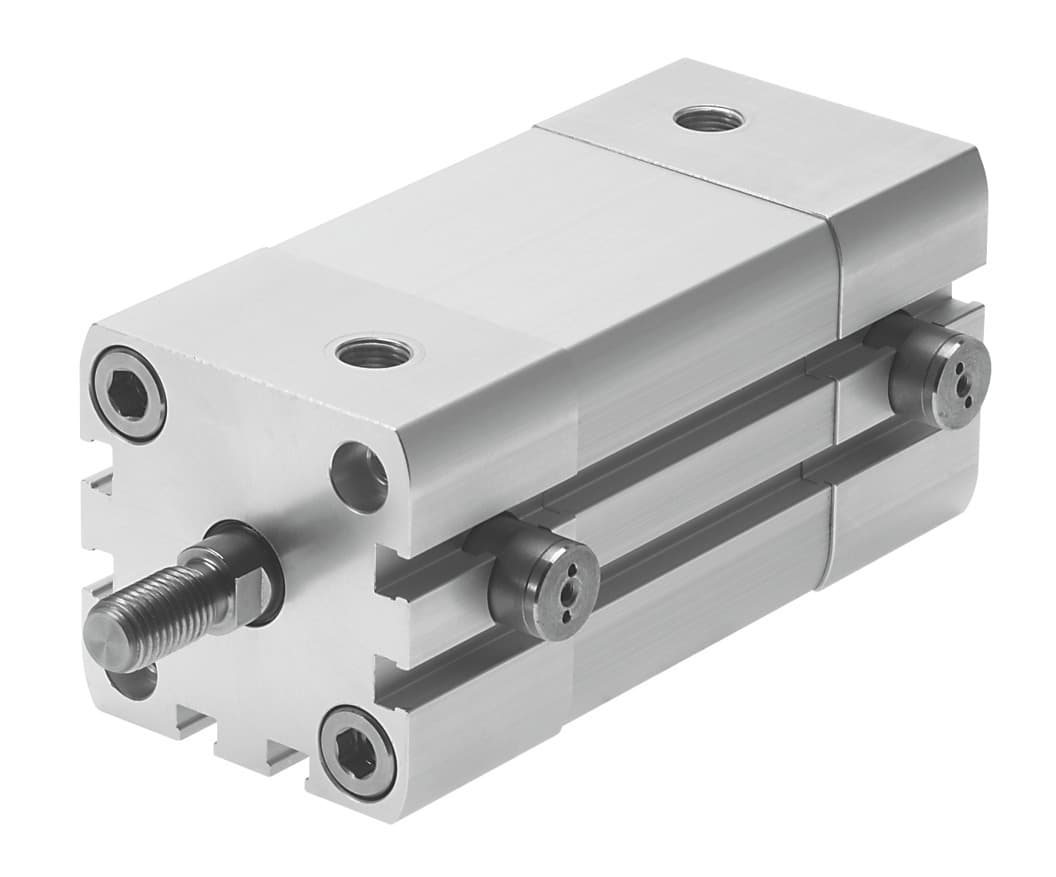

Product Model

adn-40- -el-

Key Features

- 1The Festo ADN-40 series features a compact design, reducing installation space by up to 50% compared to standard ISO cylinders.

- 2Equipped with elastic cushioning rings/pads at both ends, these cylinders absorb residual energy, making them suitable for medium to heavy loads and high-speed applications.

- 3The ADN series includes magnetic piston rods for contactless position sensing via proximity sensors, enhancing precision and reliability.

- 4These cylinders offer flexible mounting options, including female threads, through-hole mounts, and internal threaded mounts, ensuring easy installation in various settings.

- 5Constructed with high-alloy steel piston rods and smooth anodized wrought aluminum alloy cylinder barrels, these cylinders provide robust performance and long service life.

Technical Specifications

Detailed engineering parameters based on manufacturer documentation

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Stroke | 10mm 400mm | Piston diameter | 40 mm |

| Piston rod thread | M10x1.25 | Based on norm | ISO 21287 |

| Cushioning | Elastic cushioning rings/pads at both ends | Mounting position | Any |

| Piston rod end | Internal thread | Structural design | Piston Piston rod Cylinder barrel |

| Position sensing | For proximity sensor | Variants | With end-position locking at both ends With rear end-position locking With front end-position locking Extended external thread piston rod Special thread on piston rod Extended piston rod Laser etched rating plate |

| Operating pressure | 2.5bar 10bar | Mode of operation | Double-acting |

| Operating medium | Compressed air as per ISO 8573-1:2010 [7:4:4] | Information on operating and pilot media | Operation with oil lubrication possible (required for further use) |

| Corrosion resistance class (CRC) | 2 - Moderate corrosion stress | LABS (PWIS) conformity | VDMA24364-B1/B2-L |

| Ambient temperature | -20°C 80°C | Impact energy in the end positions | 0.7J |

| Theoretical force at 6 bar, retracting | 686N | Theoretical force at 6 bar, advancing | 754N |

| Additional moving mass per 10?mm stroke | 9g | Type of mounting | With internal thread With accessories |

| Pneumatic connection | G1/8 | Note on materials | RoHS-compliant |

| Cover material | Wrought aluminum alloy Anodized | Piston rod material | High-alloy steel |

| Material of cylinder barrel | Wrought aluminum alloy Smooth anodized | Manufacturer ID | 548217 |

Specifications may be subject to change without notice